Q: Bearings for offshore drilling machinery.

A: China's first 1200m deep well oil drilling rig with independent intellectual property rights was successfully developed by PetroChina Baoji Oil Machinery Co., Ltd. in 2007. This drilling rig is the first 1200m AC variable frequency electric drive drilling rig for land use in China and abroad, and is also the most technologically advanced deep well land oil drilling rig in the world. It was ordered by Sinopec Group for the exploration and development of the 8875m exploration well in Puguang gas field.

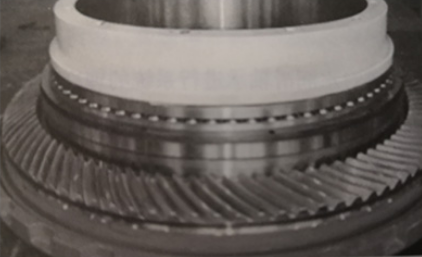

The main bearings for this drilling rig are developed and produced by ZWZ. Its main bearing speed reaches 300r/min, and the main bearings are developed simultaneously with the 12,000m drilling rig; in order to ensure the high load and high speed working conditions, it is particularly emphasized that the rings and steel balls are made of carburized steel (G20Cr 2Ni4A), and the bearing accuracy is above P5. The main bearing scheme was finally determined, with the code 2327/1374X4/HCEP5, which is a double-row thrust angular contact ball bearing (see the figure below), with case-hardened steel rings and steel balls and a machined cage. The main bearing for the 12000m drilling rig is also the first in China; the successful development of this bearing represents that Wazhou has taken a leading position in the field of drilling rig bearings, and the overall performance and manufacturing quality of the product have reached the advanced level of the international industry.